Only individuals that are trained and tested on the location’s Lockout, Tagout and Tryout procedure can Lockout, Tagout and Tryout.

The location must determine who can sign or authorize the Lockout, Tagout and Tryout permits. This information is to be included in the location Lockout, Tagout and Tryout procedures. These designated individuals must be trained and tested for comprehension before they sign permits.

Whenever major repair, replacement, renovation or modification of existing non-lockable machinery or equipment is performed a lockable energy isolating device must be installed. All new equipment must be designed to accept a lockout device wherever unexpected energization, start-up, or release of stored energy.

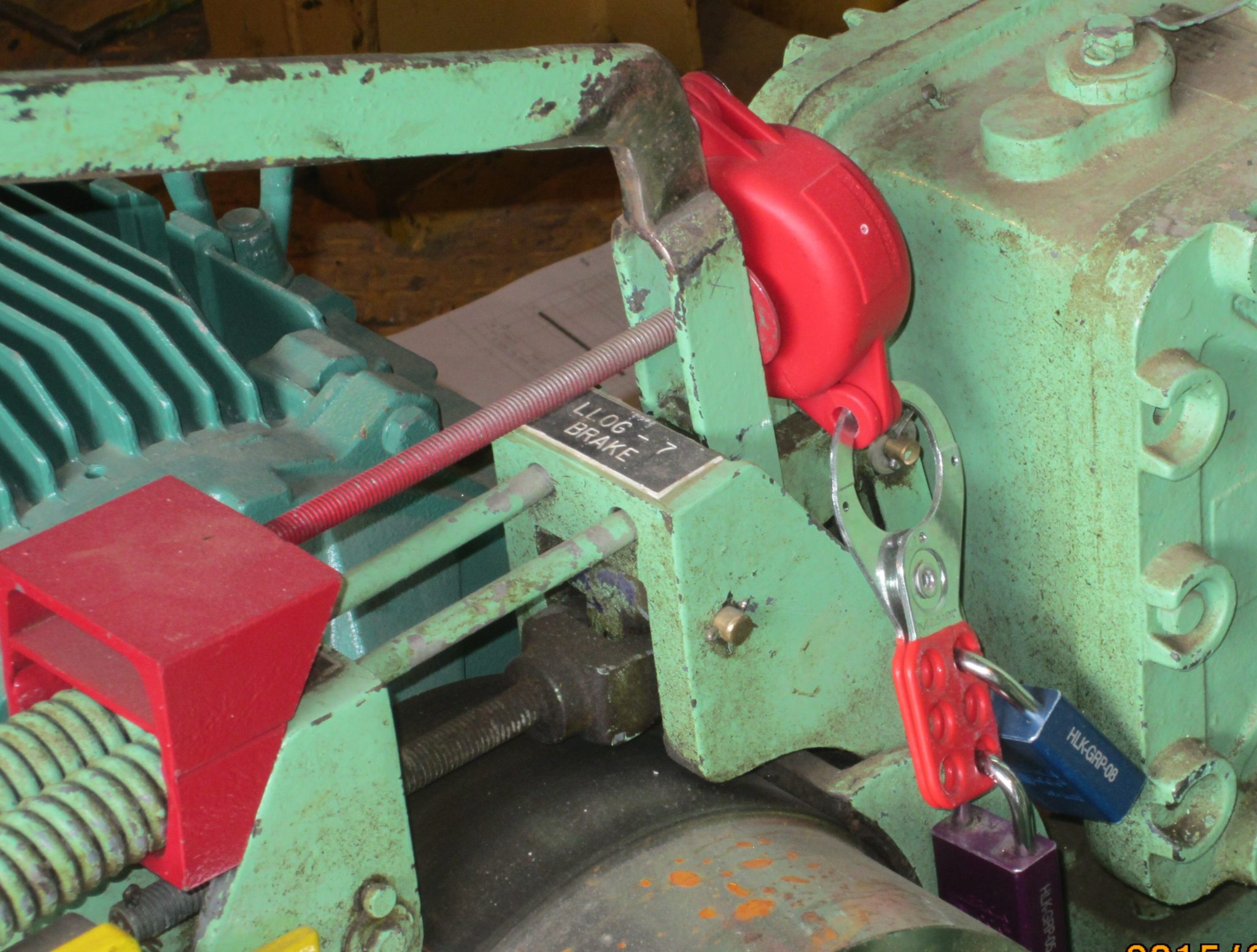

Site procedures must address all energy sources; such as, electrical, mechanical, hydraulic, and pneumatic. Stored energy, as in springs, elevated machinery members, rotating flywheels, hydraulic systems, and process materials in all forms (gas, liquid, or solid) must be considered for isolation (lockout/tagout). Pressure must be dissipated or restrained by methods such as blocking, bleeding down, etc.

Notify all affected people that a lockout/tagout will be taking place and the reason why. Written notification is the preferred method of communication.